UN macchina riempitrice di capsule completamente automatica è un'apparecchiatura avanzata progettata per semplificare il processo di riempimento di capsule vuote con polvere o granuli. Ampiamente utilizzata nell'industria farmaceutica, questa riempitrice automatica di capsule è in grado di gestire sia capsule di gelatina dura che capsule vegetali. Di seguito, troverete tutto ciò che dovete sapere su questa versatile ed efficiente macchina riempitrice automatica di capsule.

La macchina è in genere composta da diversi componenti chiave: una tramoggia per contenere le materie prime, un sistema di dosaggio per una misurazione precisa, un sistema di orientamento delle capsule per garantire il corretto allineamento, una stazione di riempimento dove avviene il riempimento vero e proprio e un meccanismo di chiusura per sigillare la capsula dopo il riempimento. L'intero processo di riempimento delle capsule è automatizzato, dal momento in cui le capsule vengono alimentate nella riempitrice automatica fino allo scarico finale delle capsule riempite.

Automazione: la macchina funziona con un intervento umano minimo o nullo, aumentando significativamente la produttività e riducendo i costi di manodopera.

Precisione: grazie a un meccanismo di dosaggio preciso, viene garantita la costanza del riempimento, fondamentale per mantenere la qualità e l'efficacia delle capsule.

Flessibilità: progettata per adattarsi a diverse dimensioni di capsule, offre flessibilità per diversi tipi e volumi di prodotto.

Facilità d'uso: l'interfaccia intuitiva e la semplicità d'uso rendono la macchina adatta a operatori con diversi livelli di esperienza.

Facile manutenzione: grazie al design modulare e ai componenti facilmente accessibili, la pulizia e la manutenzione quotidiane risultano semplici.

Per mantenere l'efficienza e la durata della vostra macchina automatica per il riempimento di capsule, una pulizia regolare è essenziale. Non solo garantisce il funzionamento regolare della macchina, ma aiuta anche a produrre capsule di alta qualità in modo continuativo. In questa guida, vi guideremo passo dopo passo nella pulizia della vostra macchina automatica per il riempimento di capsule, assicurandovi che ogni componente sia accuratamente pulito e pronto per la produzione successiva.

Per prima cosa, spegnere l'alimentazione elettrica e scollegare la macchina dalla rete elettrica. Questo garantisce la sicurezza degli operatori durante la pulizia. Inoltre, impedisce l'avvio accidentale della macchina automatica per il riempimento delle capsule mentre è in funzione.

Rimuovere tutte le capsule e la polvere rimaste nella macchina. Se sono presenti capsule parzialmente riempite, smaltirle secondo le procedure operative standard (SOP) dell'azienda. Svuotare la tramoggia e rimuovere eventuali residui.

Preparate tutti i prodotti necessari per la pulizia. Avrete bisogno di: Spazzola morbida o aria compressa per rimuovere la polvere. Soluzione detergente delicata e acqua. Panno in microfibra o spugna morbida. Guanti per proteggere le mani. Disinfettante appropriato secondo le linee guida della struttura.

Iniziare pulendo le superfici esterne della macchina riempitrice automatica di capsule. Utilizzare un panno in microfibra imbevuto di una soluzione detergente per pulire tutte le superfici visibili. Prestare particolare attenzione alle aree toccate o maneggiate di frequente, come il pannello di controllo del PLC e le maniglie.

Nel tempo, la tramoggia e il sistema di dosaggio possono accumulare residui di polvere. Utilizzare aria compressa ad alta pressione o una spazzola morbida per rimuovere i pellet staccati. Quindi, pulire le parti rimovibili della tramoggia e del sistema di dosaggio con acqua tiepida e sapone. Risciacquare accuratamente e lasciare asciugare naturalmente prima di rimontare.

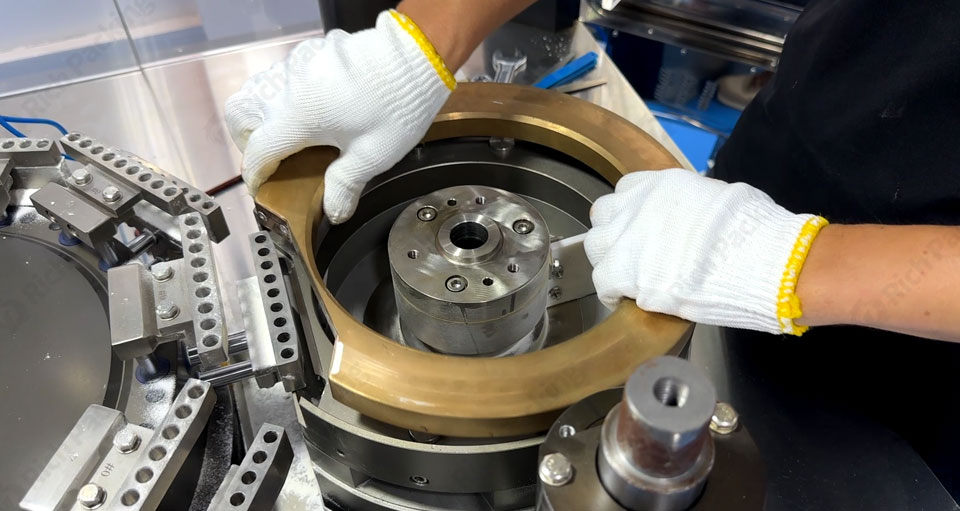

Questo componente garantisce il corretto orientamento della capsula per il riempimento. Utilizzare la spazzola morbida per rimuovere delicatamente l'accumulo di polvere attorno ai perni di orientamento. Se il sistema di orientamento è modulare, si consiglia di rimuovere i perni per una pulizia più accurata.

La stazione di riempimento è il luogo in cui avviene il riempimento vero e proprio. Utilizzare con cautela una spazzola morbida o aria compressa per rimuovere eventuali residui. Pulire l'ugello di riempimento e le altre parti rimovibili con acqua tiepida e sapone. Controllare che le porte di scarico non presentino segni di usura o danni e sostituirle se necessario.

Il meccanismo di chiusura sigilla la capsula dopo il riempimento. Pulire la piastra di tenuta e tutte le altre parti coinvolte nel processo di tenuta. Verificare attentamente la presenza di eventuali detriti o accumuli di polvere e rimuoverli con cura.

Per la pulizia interna, seguire le istruzioni del produttore. Alcune macchine potrebbero richiedere l'uso di soluzioni o metodi di pulizia specifici. Se ci sono aree difficili da raggiungere, si consiglia di utilizzare una spazzola morbida a manico lungo o gli strumenti di pulizia dedicati.

Dopo la pulizia, è importante disinfettare la macchina riempitrice automatica di capsule per prevenire la contaminazione. Utilizzare un disinfettante approvato e adatto alle apparecchiature farmaceutiche. Seguire le istruzioni del produttore della macchina riempitrice automatica di capsule per quanto riguarda i rapporti di diluizione e i tempi di contatto. Assicurarsi che tutte le superfici della macchina riempitrice automatica di capsule siano coperte uniformemente e lasciare agire il disinfettante per il tempo consigliato prima di risciacquare o asciugare.

Una volta puliti e disinfettati tutti i componenti, eseguire un'ispezione finale per assicurarsi che tutto sia in buone condizioni. Verificare la presenza di usura, danni o corrosione. Sostituire eventuali componenti danneggiati prima di rimontare la macchina. Durante il rimontaggio, assicurarsi che tutti i componenti siano saldamente in posizione e correttamente allineati.

Per mantenere la tua macchina automatica per il riempimento di capsule al massimo delle sue prestazioni, stabilisci un programma di manutenzione regolare. Questo dovrebbe includere la lubrificazione delle parti mobili, il controllo dell'usura e la sostituzione di materiali di consumo come guarnizioni e guarnizioni quando necessario. La registrazione delle attività di manutenzione può aiutarti a tenere traccia di quando un'attività è stata eseguita l'ultima volta e quando deve essere eseguita nuovamente.

Pulire la vostra macchina automatica per il riempimento di capsule non significa solo mantenerla in ordine: è fondamentale per garantirne la longevità e preservare la qualità delle capsule prodotte. Seguendo i passaggi dettagliati, potrete garantire che la macchina automatica per il riempimento di capsule funzioni in modo efficiente e senza intoppi. Ricordate, una manutenzione regolare è fondamentale per evitare tempi di fermo e costose riparazioni. Quindi, fate della pulizia e della manutenzione della vostra macchina automatica per il riempimento di capsule una priorità.

Guangdong Rich Packing Machinery Co., Ltd. vanta oltre 31 anni di esperienza nella produzione di macchine per il riempimento di capsule. Abbiamo instaurato una collaborazione a lungo termine con aziende leader nei settori farmaceutico e dei prodotti sanitari e forniamo aziende Fortune 500 da oltre 10 anni. GSK, UCB, USPHARMA e ROBINSON PHARMA sono nostri clienti di lunga data. Oltre a fornire loro servizi di installazione e messa in servizio in loco, forniamo loro anche formazione regolare e pulizia delle macchine, e forniamo loro documentazione tecnica completa, video operativi e procedure operative standard. Se avete bisogno di migliorare gli standard per la produzione automatica di macchine per il riempimento di capsule, vi preghiamo di contattarci. contattaci .