Quando si entra nel mondo della produzione farmaceutica, pressa per compresse è un'attrezzatura fondamentale che trasforma la polvere in compresse precise e uniformi. Questa macchina non è solo un macchinario — è il cuore della produzione delle compresse, responsabile della conversione dei composti farmaceutici grezzi nei farmaci che migliorano e salvano vite umane.

Una comprimitrice è un dispositivo meccanico progettato per comprimere materiali in polvere in compresse di dimensioni, forma e peso uniformi. Si tratta essenzialmente di una macchina sofisticata che trasforma ingredienti in polvere sfusi in forme farmaceutiche solide e facilmente consumabili, colmando il divario tra le materie prime e i prodotti medicinali finali.

Funzioni chiave di una pressa per compresse

- Misurare con precisione le quantità di polvere

- Comprimere le polveri in una forma predeterminata

- Garantire peso e densità della compressa uniformi

- Produrre compresse con caratteristiche di rilascio specifiche

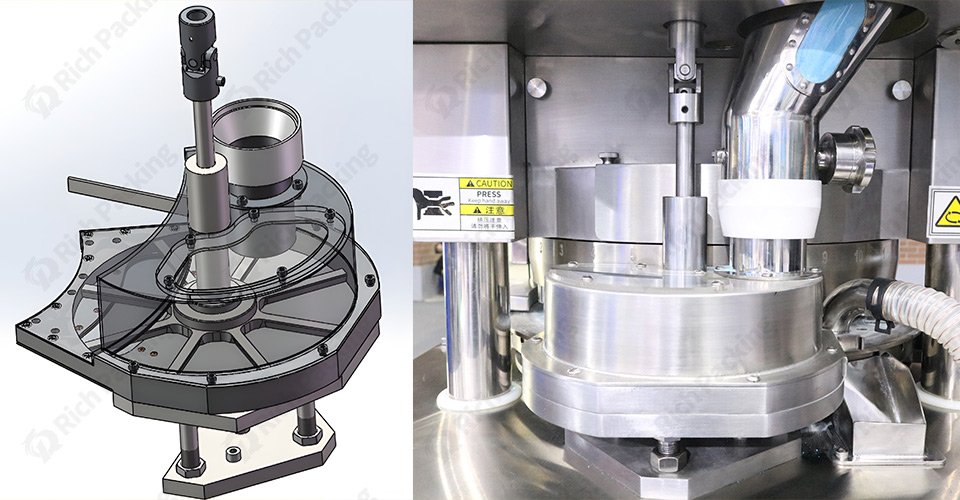

La tramoggia funge da punto di ingresso iniziale per l'introduzione del materiale nel processo di pressatura delle compresse. Svolge un ruolo cruciale nella gestione del flusso di materiali in polvere, garantendo un'alimentazione costante e controllata alle cavità dello stampo. Prevenendo problemi come la formazione di ponti di materiale e mantenendo un flusso di polvere costante, la tramoggia è fondamentale per ottenere una produzione uniforme di compresse.

Funzioni chiave di un sistema di tramoggia

- Conserva le materie prime in polvere

- Garantisce un flusso di polvere costante

- Previene la formazione di ponti o di depositi di materiale

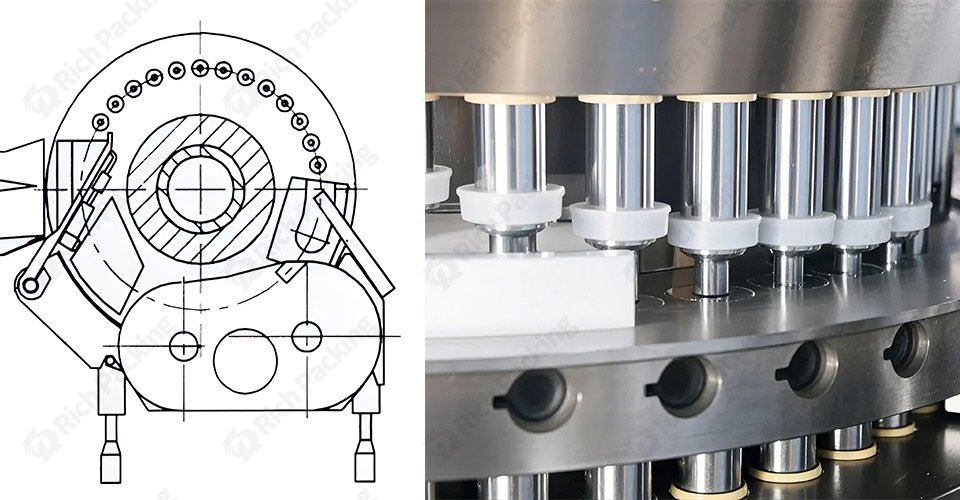

Il tavolo portastampi rappresenta il cuore meccanico della comprimitrice. Questa piattaforma rotante è responsabile dell'alloggiamento di più cavità e della gestione del complesso processo di formazione delle compresse. La sua rotazione continua e la sua progettazione di precisione consentono la trasformazione di polveri sciolte in compresse dalla forma perfetta, determinando la capacità produttiva complessiva e l'efficienza del processo produttivo.

Funzioni chiave di un tavolo portastampi

- Ruota continuamente nelle presse rotative per compresse

- Contiene più cavità di matrice

- Fornisce il meccanismo primario per la formazione delle compresse

- Determina la capacità produttiva complessiva

Assemblaggio punzone e matrice

Questo componente di precisione è il luogo in cui avviene la vera magia della creazione delle compresse. I punzoni superiore e inferiore lavorano in perfetta armonia per modellare, comprimere e formare le compresse con una precisione microscopica. Realizzati in acciaio temprato, questi componenti definiscono ogni caratteristica critica della compressa finale, dal peso e spessore alla densità e all'integrità strutturale.

Funzioni chiave

- I punzoni superiori e inferiori creano la forma della tavoletta

- Progettato con precisione per tolleranze microscopiche

- Determinare il peso, lo spessore e la densità della compressa

- Realizzato in acciaio temprato per una maggiore durata

Tipi di presse per compresse

Le comprimitrici non sono macchine universali, ma piuttosto apparecchiature specializzate progettate per soddisfare diverse esigenze produttive. I due principali tipi di comprimitrici offrono vantaggi unici, adatti a diverse scale e requisiti di produzione.

|

Caratteristica |

Pressa per compresse a punzone singolo |

Pressa per compresse rotativa |

|

Scala di produzione |

Su piccola scala |

Ad alto volume |

|

Modalità operativa |

Manuale o semiautomatico |

Completamente automatizzato |

|

Applicazioni tipiche |

Ricerca e sviluppo, piccoli lotti |

Produzione farmaceutica industriale |

|

Compresse al minuto |

Decine a centinaia |

Migliaia |

|

Investimento iniziale |

Inferiore |

Più alto |

|

Complessità |

Semplice |

Avanzato |

La compressione diretta rappresenta l'approccio più semplice alla produzione di compresse. Questo metodo prevede la compressione diretta degli ingredienti in polvere senza ulteriori fasi di lavorazione, rendendolo ideale per composti termosensibili. Il successo dipende in larga misura da eccipienti accuratamente selezionati, in grado di facilitare una compressione uniforme e la formazione della compressa.

Progettato specificamente per materiali sensibili all'umidità, granulazione a secco Offre un approccio specializzato alla pressatura delle compresse. Il processo prevede la compattazione delle polveri in masse dense senza l'introduzione di liquidi, prevenendo così potenziali interazioni chimiche. Mantenendo le proprietà originali della polvere e migliorandone la comprimibilità, la granulazione a secco offre una soluzione fondamentale per formulazioni farmaceutiche complesse.

Il più complesso dei metodi di compressione, granulazione a umido Introduce un legante liquido nei materiali in polvere, creando granuli attraverso l'aggiunta controllata di umidità. Questa tecnica migliora significativamente le caratteristiche di scorrimento della polvere e migliora l'integrità strutturale della compressa. Sebbene richieda più manodopera, la granulazione a umido offre un controllo senza pari sulle proprietà fisiche e chimiche della compressa finale.

L'applicazione della forza di compressione è un delicato equilibrio che influenza direttamente le prestazioni della compressa. Forze di compressione basse producono compresse friabili con velocità di dissoluzione maggiori ma minore resistenza meccanica. Al contrario, forze di compressione elevate creano compresse più dure con maggiore resistenza meccanica ma potenzialmente più lente caratteristiche di dissoluzione.

Comprendere le caratteristiche delle polveri è fondamentale per una produzione di compresse di successo. Fattori come la distribuzione granulometrica, il contenuto di umidità, le proprietà di scorrimento, la comprimibilità e la coesione influiscono direttamente su ogni fase della formazione della compressa. Queste complesse proprietà determinano non solo il processo di produzione, ma anche la qualità finale, le prestazioni e l'efficacia del prodotto farmaceutico.

La pressatura delle compresse è irta di potenziali complicazioni. Problemi di flusso della polvere possono portare a un'alimentazione incoerente del materiale e a un riempimento non uniforme dello stampo. Le difficoltà di compressione possono causare variazioni di peso, incoerenze nella durezza, intrappolamento di aria e complicazioni legate all'attrito. I produttori di successo devono sviluppare sofisticate strategie di diagnostica e ottimizzazione per superare queste sfide intrinseche.

Tecnologia di compressione delle compresse È la parte centrale del processo farmaceutico, in cui le polveri delle materie prime vengono trasformate in compresse uniformi e di alta qualità mediante comprimitrici di precisione. Dalle comprimitrici a punzone singolo a quelle rotative, diversi metodi di compressione e il controllo preciso dei parametri chiave garantiscono la qualità, la stabilità e l'efficacia dei farmaci, riflettendo la natura scientifica e precisa della tecnologia farmaceutica.