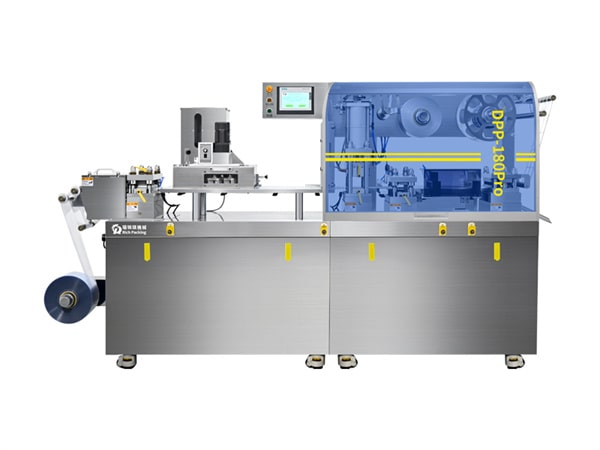

Macchine confezionatrici blister chiamare anche macchina confezionatrice blister O macchina blister Hanno rivoluzionato il packaging in diversi settori, garantendo sicurezza, longevità e praticità per il consumatore. Questo articolo approfondisce le ragioni del loro utilizzo diffuso, i settori che ne beneficiano maggiormente e i fattori cruciali da considerare nella scelta di una blisteratrice.

Le macchine blisteratrici offrono diversi vantaggi che rendono il produttore un'opzione prioritaria per il confezionamento. Ecco i motivi principali:

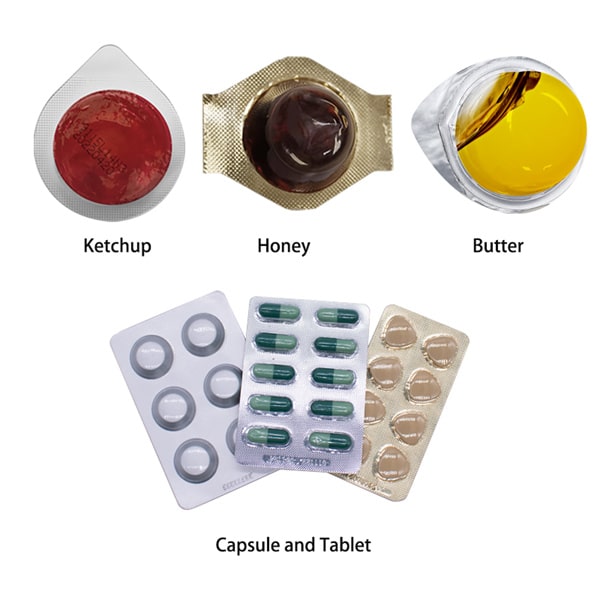

I blister offrono un'eccellente protezione da fattori ambientali come umidità, ossigeno e contaminazione. Questo è particolarmente importante per i prodotti sensibili a questi elementi, come compresse, capsule, miele, ketchup, burro, ecc. Gli scomparti ermeticamente sigillati garantiscono che il prodotto si mantenga sicuro ed efficace fino alla data di scadenza.

Il confezionamento in blister funge da deterrente contro le manomissioni. Gli scomparti trasparenti e sigillati rendono immediatamente evidente se un prodotto è stato compromesso, garantendo la sicurezza del consumatore e preservando l'integrità del marchio.

I blister sono progettati per essere facili da usare da parte dei consumatori. Offrono un confezionamento monodose, particolarmente vantaggioso per i farmaci, rendendo più facile per i pazienti rispettare i propri schemi posologici. Inoltre, la confezione trasparente consente ai consumatori di vedere il prodotto mentre lo sfogliano, migliorando l'esperienza d'acquisto.

Le macchine blisteratrici semplificano il processo di confezionamento, riducono notevolmente i costi di manodopera e aumentano i volumi di produzione nel contempo. I sistemi automatizzati riducono gli errori umani e accelerano i tempi di produzione, rendendoli soluzioni convenienti per i produttori.

Queste macchine possono gestire diverse tipologie di prodotti, da pillole e compresse a hardware ed elettronica. La versatilità nel design e nelle funzioni consente ai produttori di utilizzare il confezionamento in blister per diverse linee di prodotto senza dover ricorrere a più tipologie di macchinari per il confezionamento.

Le macchine blisteratrici sono utilizzate in un'ampia gamma di settori, ognuno dei quali sfrutta la tecnologia per soddisfare specifiche esigenze di confezionamento. Ecco alcuni dei principali settori:

L'industria farmaceutica è forse il maggiore utilizzatore di macchine blisteratrici. I farmaci in compresse, capsule o pastiglie vengono comunemente confezionati utilizzando blister. La protezione da umidità, contaminazione e manomissione è fondamentale per garantire l'efficacia e la sicurezza dei farmaci.

I blister sono ampiamente utilizzati per il confezionamento di piccoli prodotti alimentari come gomme da masticare, caramelle e snack. La possibilità di fornire porzioni monodose è particolarmente interessante in questo settore. Inoltre, confezionamento in blister prolunga la durata di conservazione dei prodotti deperibili offrendo chiusure ermetiche.

Piccoli componenti elettronici e accessori, come batterie, chiavette USB e cuffie, sono spesso confezionati in blister. La confezione trasparente consente ai consumatori di vedere il prodotto, mentre il sigillo protettivo garantisce che gli articoli rimangano al sicuro da danni e manomissioni.

I blister sono comuni nel confezionamento di vari beni di consumo, tra cui giocattoli, prodotti per la cura della persona, cosmetici e articoli per la casa. Utilizzando questo tipo di imballaggio, il prodotto può essere più attraente sugli scaffali dei negozi, con conseguente incremento delle vendite.

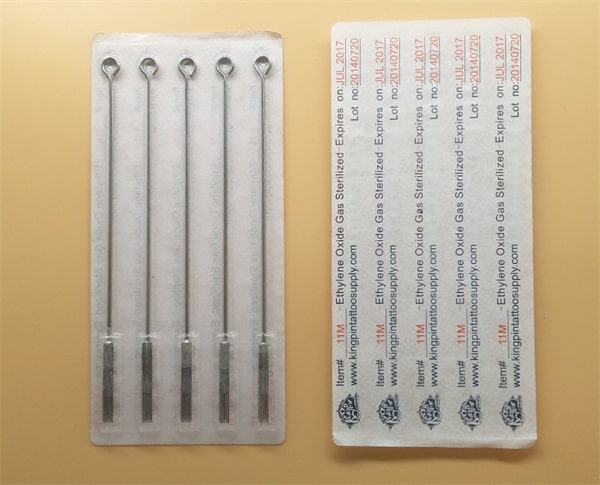

Anche i dispositivi e le forniture mediche, come siringhe, aghi e kit diagnostici, traggono vantaggio dal confezionamento in blister. L'ambiente sterile garantito dalla confezione sigillata è fondamentale per garantire l'igiene e la sicurezza di questi prodotti.

La scelta della blisteratrice più adatta alle tue esigenze richiede diverse considerazioni. Ecco alcuni fattori chiave che ti guideranno nella decisione:

Valutare la capacità produttiva di una blisteratrice è fondamentale. Deve essere in linea con le attuali esigenze produttive e avere la flessibilità necessaria per ampliare la produzione, se necessario. Le macchine con una maggiore produttività possono gestire volumi maggiori, rendendole adatte a produttori con elevati requisiti di produzione. Tuttavia, per le attività più piccole, una macchina con una capacità produttiva moderata potrebbe essere più conveniente.

Le caratteristiche del prodotto finito giocano un ruolo significativo nella scelta della macchina giusta. Considera i seguenti aspetti:

Dimensioni e forma del prodotto : Assicurati che la macchina sia adatta alle dimensioni e alle forme dei tuoi prodotti. Alcune macchine offrono stampi personalizzabili per adattarsi alle specifiche specifiche del prodotto.

Compatibilità dei materiali : Prodotti diversi potrebbero richiedere tipi specifici di materiali di imballaggio, come PVC, PVDC o alluminio. Verificare che la macchina sia in grado di gestire i materiali che si intende utilizzare.

Requisiti di sigillatura : A seconda del prodotto, potrebbero essere necessari metodi di sigillatura specifici, come la termosaldatura o la formatura a freddo. Scegli una macchina che offra la tecnica di sigillatura più adatta al tuo prodotto.

Progettazione del packaging : Se il tuo prodotto richiede design di imballaggio complessi, come blister multiscomparto o confezioni combinate, assicurati che la macchina sia in grado di offrire queste caratteristiche.

Le blisteratrici spaziano da semiautomatiche a completamente automatiche. Il livello di automazione influisce sulla velocità, l'efficienza e il fabbisogno di manodopera del processo di confezionamento. Le blisteratrici completamente automatiche sono adatte alla produzione di massa in grandi stabilimenti farmaceutici, mentre le macchine semiautomatiche possono essere sufficienti per i piccoli produttori.

Scegliete una blisteratrice che faciliti la sostituzione dello stampo e la manutenzione. Cercate caratteristiche come il funzionamento passo passo, la facilità di pulizia e le procedure di manutenzione rapide. Questo ridurrà i tempi di fermo produzione e aumenterà la sicurezza.

Sebbene l'investimento iniziale sia un fattore critico, è essenziale valutare il ROI a lungo termine. Quando si valuta il rapporto costo-efficacia della macchina, si considerino fattori come l'efficienza energetica, la riduzione degli sprechi e il potenziale risparmio di manodopera.

Un supporto e un'assistenza affidabili da parte del produttore sono essenziali per il corretto funzionamento della vostra blisteratrice. Assicuratevi che il produttore di blister disponga di un team in grado di supportare un servizio post-vendita di qualità, come formazione, fornitura di ricambi, ecc.

Conclusione

Le blisteratrici sono strumenti indispensabili in diversi settori, offrendo protezione, praticità per il consumatore ed efficienza produttiva senza pari. Quando si devono confezionare prodotti come pillole, compresse di latte, compresse, capsule, caramelle gommose, liquidi per sigarette elettroniche, siringhe monouso, oggetti di forma speciale, compresse di miele, iniezioni, fiale e altri prodotti di grandi dimensioni, queste macchine svolgono un ruolo cruciale nel garantire l'integrità del prodotto e migliorarne l'appeal sul mercato. Nella scelta di una blisteratrice, è essenziale considerare la capacità produttiva, le caratteristiche del prodotto, il livello di automazione, la facilità d'uso, i costi e il supporto del produttore. Valutando attentamente questi fattori, i produttori possono selezionare la macchina giusta per soddisfare le loro esigenze specifiche e ottenere prestazioni di confezionamento ottimali.