Le macchine automatiche per il conteggio delle compresse e le macchine conta-capsule stanno rivoluzionando il modo in cui vengono confezionate compresse, capsule e persino caramelle gommose, dalle piccole farmacie alle grandi fabbriche di integratori. Questo articolo esplora come le moderne macchine conta-capsule per compresse, in particolare le macchine conta-compresse automatiche e le macchine conta-pillole, stiano emergendo e cambiando il panorama del packaging dell'industria farmaceutica.

1. Che cos'è una macchina conta-capsule e compresse?

Una macchina conta-capsule per compresse, nota anche come macchina conta-compresse, macchina conta-pillole o macchina conta-capsule, è un'apparecchiatura automatizzata progettata per contare e riempire forme di dosaggio solide come compresse, capsule, softgel e persino caramelle gommose in flaconi o contenitori ad alta velocità e precisione.

Queste macchine automatiche per il conteggio delle compresse sono ampiamente utilizzate nei settori farmaceutico, nutraceutico e della produzione di integratori. Garantiscono che ogni flacone contenga il numero esatto di unità, riducendo drasticamente il lavoro manuale, l'errore umano e gli sprechi di prodotto. Queste macchine sono disponibili in vari modelli, che vanno dai contatori di compresse da tavolo ai contatori completamente automatici.

• Contatori di capsule per tablet da tavolo

• Macchine automatiche per il conteggio di compresse/capsule

• Macchine per il conteggio delle caramelle gommose

• Macchina contatrice con telecamera ad alta velocità CCD

Una macchina contatrice automatica, che si tratti di una macchina conta-compresse, di una macchina conta-capsule o di una macchina conta-pillole, si basa su una tecnologia avanzata di sensori e pannelli vibranti per garantire che ogni compressa o capsula venga contata accuratamente e distribuita in flaconi o contenitori. Queste macchine per il conteggio e il riempimento di compresse sono progettate per garantire precisione, velocità e conformità agli standard farmaceutici.

1) Sistema di alimentazione a vibrazione

Il processo inizia con un sistema di alimentazione a vibrazione che distribuisce i prodotti in modo uniforme su pannelli di conteggio. Le macchine contatrici di capsule e compresse ad alta velocità utilizzano pannelli vibranti multicanale per grandi volumi.

2

) Tecnologia di conteggio ad alta precisione

La maggior parte delle macchine conta-compresse elettroniche utilizza sensori fotoelettrici per rilevare ogni unità in transito. Ciò garantisce che ogni pillola, compressa o capsula venga contata con precisione, un aspetto fondamentale per le macchine conta-compresse in farmacia e per le attività farmaceutiche ad alta produttività.

3) Meccanismo di scarto dei rifiuti

Modelli avanzati, come le macchine automatiche per il conteggio delle capsule di compresse con telecamera CCD, dotate di sistemi di scarto che rilevano i prodotti rotti o irregolari e li rimuovono automaticamente, garantendo la precisione del confezionamento.

4) Sistema di riempimento e imbottigliamento

Una volta raggiunto il conteggio target, la macchina riempie automaticamente il prodotto nei flaconi. Le macchine conta-riempitrici per compresse e le macchine conta-riempitrici per capsule si integrano con le macchine tappatrici ed etichettatrici per semplificare l'intero processo di confezionamento.

5) Interfaccia di controllo PLC

Gli operatori possono monitorare l'intero flusso di lavoro tramite un'interfaccia touchscreen PLC, consentendo regolazioni per diverse dimensioni di pillole, quantità di lotti o cambi, ideale per le aziende che utilizzano macchine contatrici cinesi o che importano da fornitori di macchine contatrici per compresse a livello globale.

Le macchine contatrici di compresse e capsule offrono ai produttori farmaceutici e nutraceutici un vantaggio significativo in termini di ottimizzazione della produzione, miglioramento della precisione e conformità ai requisiti normativi. Di seguito sono riportati i principali vantaggi:

• Alta precisione: Le moderne macchine conta-pillole eliminano gli errori manuali, garantendo che ogni flacone contenga esattamente il numero corretto di compresse o capsule.

• Efficienza migliorata: Una macchina automatica per il conteggio delle capsule può processare migliaia di unità all'ora, riducendo drasticamente i colli di bottiglia nelle linee di produzione.

• Versatilità: Le macchine contapillole possono contare compresse dure, capsule molli, capsule di gelatina o vegetariane, masticabili e persino caramelle gommose, utilizzando una speciale macchina conta-gomme.

• Conformità e tracciabilità: Per la produzione farmaceutica, le macchine contatrici elettroniche di compresse contribuiscono a soddisfare i requisiti GMP e consentono un facile monitoraggio per gli audit.

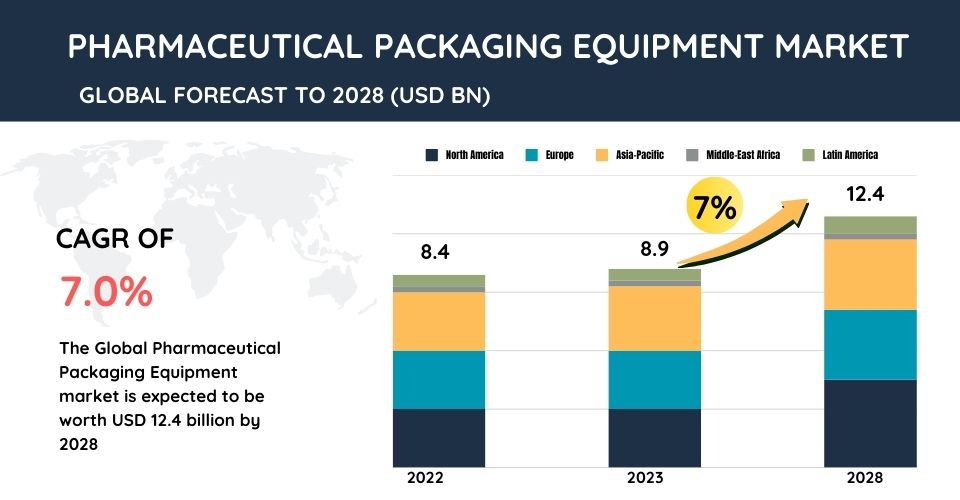

Come riportato da MarketsandMarkets, il settore globale delle apparecchiature per il confezionamento farmaceutico è stato valutato a 8,9 miliardi di dollari nel 2023 e si prevede che crescerà fino a 12,4 miliardi di dollari entro il 2028, riflettendo un tasso di crescita annuo composto (CAGR) del 7,0%. Uno dei fattori chiave che guidano questa crescita è la crescente domanda di automazione nei processi di produzione, che svolge un ruolo fondamentale in settori come quello farmaceutico, alimentare e degli integratori alimentari.

Tra questa produzione di automazione, macchine per il conteggio di compresse e capsule sono tra le attrezzature chiave di questo mercato. I principali fattori trainanti della crescita di questo mercato includono:

1) Crescente domanda di prodotti farmaceutici e integratori: L'invecchiamento della popolazione e la crescente consapevolezza sanitaria hanno aumentato significativamente la necessità sia di farmaci da prescrizione che di integratori alimentari, richiedendo soluzioni di confezionamento più efficienti e precise.

2) Progressi nell'automazione: L'automazione nel conteggio di compresse e capsule ha reso possibili linee di produzione più rapide e precise, riducendo l'errore umano e aumentando l'efficienza complessiva.

3) Conformità normativa: Le aziende farmaceutiche devono rispettare rigide normative, tra cui gli standard FDA e GMP. Il conteggio automatizzato garantisce un confezionamento accurato e conforme, salvaguardando la salute dei consumatori e mantenendo la conformità normativa.

|

Industria |

Applicazioni |

Prodotti contati |

|

Farmaceutico |

- Confezionamento di farmaci da prescrizione e da banco - Preparazione del kit per la sperimentazione clinica - Imbottigliamento conforme alle GMP |

Compresse, capsule, capsule molli, farmaci monodose. |

|

Nutraceutico e integratore |

- Imbottigliamento multivitaminico - Riempimento della capsula con estratto di erbe - Produzione a marchio privato |

Capsule, masticabili, capsule molli, compresse di collagene. |

|

Medicina veterinaria |

- Imbottigliamento di farmaci per animali - Confezionamento di additivi per mangimi - Preparazione di integratori per animali domestici |

Boli per bestiame, compresse, capsule per la salute degli animali domestici. |

|

Cosmetici e cura della pelle |

- Confezione di integratori di bellezza orale - Compresse effervescenti per la cura della pelle |

Compresse per la cura della pelle, compresse solubili per il viso, capsule di bellezza. |

|

Cibo e dolciumi |

- Imbottigliamento di caramelle/mentine - Confezione di compresse energetiche - Preparazione di alimenti funzionali |

Compresse di menta, caramelle gommose, integratori di caffè/energetici. |

|

Ricerca e ospedale |

- Preparazione del campione per la sperimentazione clinica - Erogazione di piccoli lotti - Farmacia ospedaliera |

Compresse, capsule, campioni di prova. |

Con la crescente domanda di caramelle gommose funzionali e dietetiche, aumenta anche la necessità di macchine precise per il conteggio delle caramelle gommose. Una speciale macchina per il conteggio delle caramelle gommose garantisce che le caramelle gommose morbide e di forma irregolare non vengano schiacciate o contate erroneamente durante il confezionamento. Questi contatori di caramelle gommose utilizzano un sistema di erogazione e separazione personalizzato, nonché pannelli vibranti con trattamento speciale per garantire precisione e igiene.

Ad esempio, il Macchina di riempimento e conteggio delle caramelle gommose 8D Rich Packing ha apportato alcuni miglioramenti ai dettagli, affrontando in particolare il problema delle gomme appiccicose con le seguenti caratteristiche:

• Sistema di separazione delle gomme con agitatore a spillo: Separare completamente le caramelle gommose appiccicose prima di somministrarle.

• Sistema anti-agglomerazione: Evitare che le caramelle gommose si accumulino prima di utilizzarle sui pannelli vibranti.

• Pannelli vibranti a 3 stadi rivestiti in Teflon: Evitare che le caramelle gommose si attacchino ai pannelli prima di entrare nel canale di conteggio del sensore fotoelettrico.

• Porta di scarico in PTFE allargata con sistema vibrante: Garantisce un imbottigliamento fluido delle caramelle gommose, evitando problemi di intasamento.

Scegliere la macchina conta-pillole o conta-capsule giusta è fondamentale per mantenere efficienza, precisione e scalabilità nella vostra linea di produzione. Che siate una startup produttrice di integratori o un grande produttore farmaceutico, la giusta attrezzatura garantisce precisione, riduce al minimo gli sprechi e supporta la conformità normativa.

|

Tipo di macchina |

Ideale per |

Caratteristiche tipiche |

|

Contatore di pillole manuale |

Piccole farmacie, laboratori, ospedali |

Vassoio di conteggio di base, basso costo, velocità e volume limitati. |

|

Contatore completamente automatico |

Grandi fabbriche di integratori/farmaci |

Sistema multicanale, elevata potenza, integrazione completa della linea. |

|

Contatore multicanale |

Operazioni ad alta velocità che richiedono più corsie |

Canali personalizzabili ad alta precisione (4, 8, 12, 16+), funzioni antipolvere. |

|

Contatore di capsule da tavolo |

Laboratori di ricerca e sviluppo, produttori a contratto |

Design compatto, display digitale, funzionamento plug-and-play. |

|

Macchina contatrice per telecamere CCD |

Imbottigliamento farmaceutico e nutraceutico ad alta precisione. |

Utilizza telecamere CCD industriali ad alta velocità per il conteggio basato sulle immagini; ultraveloce con rilevamento degli errori in tempo reale. |

|

Fattore |

Dettagli |

|

Volume di produzione |

Scegliete contatrici di compresse da tavolo per lotti di piccole e medie dimensioni. Per produzioni su larga scala, optate per macchine conta-compresse completamente automatiche con pannelli vibranti multi-linea. |

|

Tipo di prodotto |

Assicurati che la macchina supporti il tuo prodotto specifico: compresse dure, capsule molli, capsule, capsule trasparenti, ecc. Le macchine avanzate sono dotate di canali multipli e sistemi antipolvere per prestazioni migliori. |

|

Precisione e velocità |

Cerca caratteristiche come sensori fotoelettrici, funzione antipolvere e sistema di scarico fluido per garantire un conteggio preciso e ad alta velocità. |

|

Facilità d'uso |

I comandi touchscreen, il design modulare per un facile smontaggio e manutenzione, gli avvisi di errore intelligenti e la sostituzione dei pezzi senza attrezzi migliorano l'efficienza dell'operatore e riducono i tempi di fermo. |

|

Conformità normativa |

Le macchine devono essere conformi agli standard GMP, CE e FDA, in particolare per l'uso farmaceutico e nutraceutico. |

|

Capacità di integrazione |

Se stai automatizzando la tua linea, assicurati che la macchina possa integrarsi con riordinatori di bottiglie, inseritori di essiccante, cotonatori, tappatrici ed etichettatrici. |

Scegliere un produttore affidabile di macchine conta-compresse garantisce prestazioni a lungo termine, un migliore supporto post-vendita e la conformità alle normative. Di seguito sono elencati alcuni fornitori affidabili, sia a livello globale che cinese, noti per la qualità delle loro attrezzature:

|

Produttore |

Paese |

Punti di forza |

|

Crema |

Paesi Bassi |

Soluzioni di conteggio ad alta velocità per il settore farmaceutico e nutraceutico; sistemi ottici avanzati. |

|

IMA |

Italia |

Macchine di livello premium; parte di linee di confezionamento completamente automatizzate. |

|

Kirby Lester (Capsa) |

U.S.A. |

Contapillole compatti e semiautomatici, ideali per farmacie e ospedali. |

|

Imballaggio ricco |

Cina |

Macchine completamente automatiche a prezzi accessibili con opzioni multicanale e conformità GMP. |

|

Ruidapacking |

Cina |

Affidabile per acquirenti attenti al budget ma che richiedono un'elevata qualità; ottime prestazioni e prezzo conveniente. |

Dalle macchine conta-pillole nelle piccole farmacie alle macchine conta-capsule automatiche in ambito industriale, il passaggio all'automazione non è più un'opzione. Investire in una macchina conta-compresse e capsule non solo aumenta l'efficienza, ma migliora anche la qualità del prodotto e la reputazione del marchio. Che abbiate bisogno di una macchina conta-compresse per farmacia, di un conta-gomme o di una macchina completa per il conteggio e il riempimento di compresse, non c'è mai stato un momento migliore per esplorare il mercato.