Single-serve formats are everywhere—coffee, electrolyte powders, collagen, probiotics, sauces, shampoo samples, and many nutraceutical and pharmaceutical products. But “sachet,” “pouch,” and “stick pack” are used loosely, so teams often pick a format based on appearance first and only discover the hard constraints later: seal leaks, wrinkling, unstable portion weights, or output targets that can’t be met without constant line tuning. This article clarifies the differences and gives you a practical way to choose a format that works in real production.

A helpful starting point is flexible packaging: packages made from flexible materials (often paper, plastic film, foil, or combinations) that can change shape when filled, and commonly include bags, pouches, rollstock, wraps, and similar formats. Within that umbrella, the three terms in this title don’t sit at the same level.

Sachet packaging is best treated as a “use case” category—small, usually single-serve packs that are flat, easy to tear, and simple to distribute in cartons or displays. A sachet might be a 3-side seal, 4-side seal, or a back-seal style depending on how it’s formed and sealed. Pouch packaging is broader: it can be a flat pouch, stand-up pouch, zipper pouch, spout pouch, and many other structures, often chosen for larger volumes, shelf presence, and better dispensing or reclose features.

A stick pack is a specific narrow, long shape—usually a type of sachet packaging —designed for portability and controlled pouring. In everyday usage, many teams use ‘sachet’ as a catch-all term for small single-serve packs, so you’ll often hear stick packs described as sachets too.

sachet packaging

Most debates become easy once you focus on product behavior at the moment of filling and sealing. Powders, liquids, and granules create very different risks.

Powders often decide the format. Fine powders can be dusty, static-prone, hygroscopic, or prone to bridging, which affects both dosing stability and seal cleanliness. A flat sachet is a straightforward, familiar option for powders when the pack is poured into a cup or mixed directly. Stick packs become attractive when the user needs controlled pouring into a narrow bottle opening or when the brand wants a premium “single-dose ritual.” For multi-serve use, pouches often win because one larger pack can replace many single-serve units.

Liquids and gels are usually limited by seal contamination. A sticky syrup, cosmetic serum, or foaming liquid can creep into the seal zone and create microchannels that look sealed but leak after shipping. Liquids can still run well in sachet packaging or stick packs, but the format must be chosen together with filling method (pump type, anti-drip control) and a seal style that tolerates your real product behavior. If the volume is higher or the user needs cleaner dispensing, pouches with better opening geometry—or even spouts—can reduce complaints and leakage risk.

Granules can look easy but often cause “hidden” defects: bounce into the seal area, segregation in the hopper, or chipping that creates fines that behave like powder. If granules must stay intact, prioritize a format and process that keeps the seal area clean and filling impact gentle, even if that means slightly higher material usage.

Two formats can protect a product equally well and still feel completely different to the customer. Stick packs shine when portion control and controlled pouring are the point: supplements into a bottle, drink mixes on the go, or sample programs where pocketability matters. They also look “premium” because the long, narrow silhouette reads as intentionally dosed rather than “just a small packet.”

Flat sachets are popular because they are familiar, easy to collate, and print-friendly. Pouches move you into a different user experience: they’re often chosen for storage and dispensing, not just a single tear-and-pour moment. If you’re packaging for shelf impact, reclose convenience, or larger serving sizes, pouch packaging is usually the more natural home.

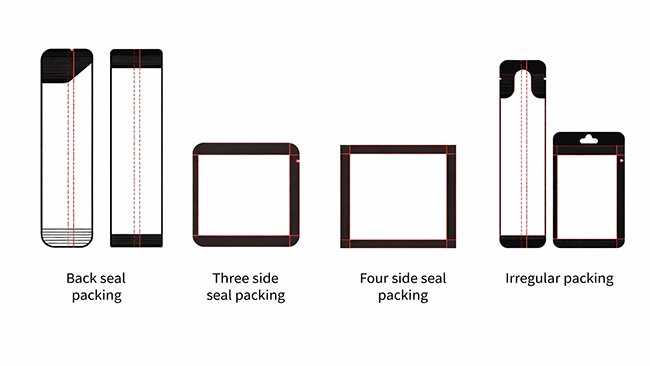

Many performance problems are really seal-structure problems. The common structures you’ll see discussed are 3-side seal, 4-side seal, and back-seal styles. In simple terms, 3-side seal pouches have three sealed edges and one edge used for filling before final sealing; 4-side seal pouches are sealed on all four sides; back-seal styles have a longitudinal seal on the back.

Instead of memorizing definitions, think in outcomes. Seal structure influences how forgiving the “fill window” is (how easily you can keep product out of the seal area), how the pack tears and pours, and how sensitive the pack is to wrinkles at speed. This is why format selection is not just branding: the seal approach changes your defect profile and your stable operating range.

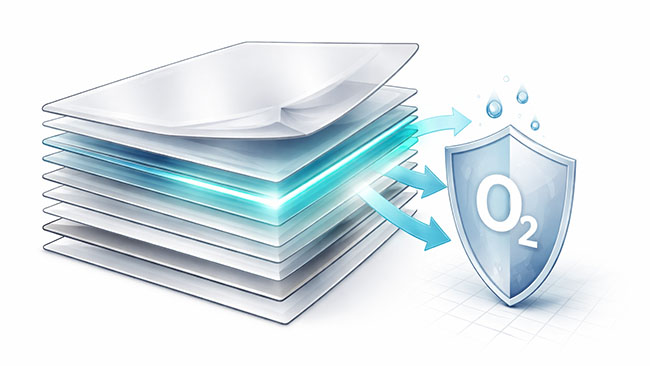

Film choice is where shelf life and manufacturability meet. Flexible packaging structures are often multilayer so you can combine printability, stiffness, barrier performance, and a sealant layer that closes reliably. For broad format selection, two practical points matter more than a long list of resin names.

First, barrier performance can change with moisture exposure. EVOH is widely used as an oxygen barrier, but it’s hygroscopic and loses much of its barrier advantage when wet unless protected within a multilayer structure. If your product or supply chain is humid, the “barrier spec” must be interpreted in the real environment, not only in ideal conditions.

multilayer film structure

Second, film stiffness and friction affect web handling. Narrow formats—especially stick packs—show tracking and wrinkling problems sooner because you have less width to absorb small tension variations. A film that is fine for a wider pouch may be too soft or too “grabby” for high-speed narrow packs, which pushes you toward better web guiding/registration control or a more suitable film structure.

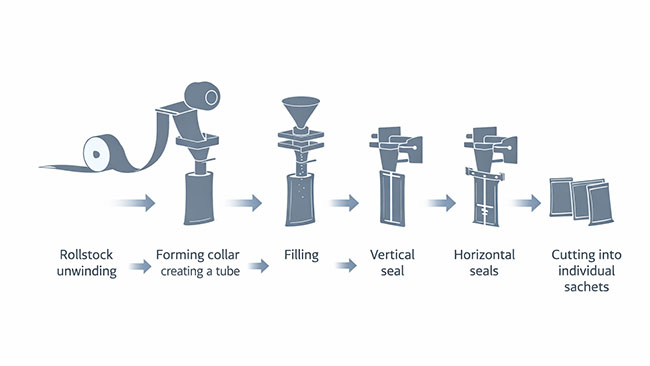

Most single-serve sachet packaging and stick packs are made on a sachet packaging machine using rollstock film—formed, filled, sealed, then cut in a repeating cycle. In vertical form/fill/seal systems, film is drawn over a forming collar into a tube, product is filled, seals are made, and the tube is cut into individual packs; commonly, the top seal of one pack becomes the bottom seal of the next.

vertical form fill seal process step by step diagram

For choosing a format, focus on what each step “demands” from you. Web handling sets stability (tension, tracking, registration). Filling must keep product out of the seal area (especially dusty powders and sticky liquids). Sealing must operate inside a reliable heat-seal window for your film, with adequate pressure and dwell time. Cutting and registration must stay synchronized so you don’t cut too close to seals or misalign graphics. When you scale output with multiple lanes, you’re multiplying these controls across lanes, which is powerful—but less forgiving if a lane drifts.

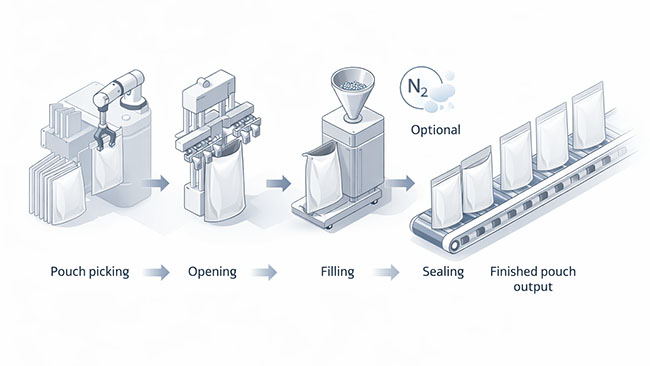

Pouches follow a slightly different logic, and in practice they’re made in two main ways.Pouch packaging can be produced in two common ways. For premade pouches (often run on a premade pouch packing machine), the line typically picks a finished pouch, opens it, fills the product, and seals it—this is common for stand-up pouches, zipper pouches, and spouted pouches because the pouch features are already built in. For form-fill-seal pouches, the machine forms the pouch from rollstock film, then fills and seals it in-line. Compared with sachet packaging and stick packs, pouches add extra handling steps (pouch picking, opening, holding, and sometimes zipper/spout integrity), so reliability often depends more on pouch handling control and fitment/zipper sealing consistency than on simple web tracking alone.

premade pouch packing machine workflow diagram

Unit film cost is only one slice of total cost. In real lines, the expensive items are waste, downtime, and rework. Sachets often stack and ship efficiently and integrate smoothly into secondary packing. Stick packs can be material-efficient per serving and improve user experience, but they can demand tighter web handling and seal uniformity at high output. Pouches often use more material per unit, yet they can reduce total packaging events if one multi-serve pouch replaces many single-serve packs, and they can improve consumer satisfaction through reclose and dispensing.

In simple terms, sachet packaging and stick packs focus on single-serve convenience and portion control; pouches are better for storage, presentation, and dispensing. Your best option is the one that reduces the most likely defect mode for your product at your target output.

If output is the deciding factor, the question becomes whether to push one lane faster or multiply lanes for stable servings-per-minute capacity.

Multi-lane stick packs earn their place when your business is truly “servings per minute”: beverage mixes, supplement powders, probiotics, sweeteners, and similar products sold at scale. Parallel lanes multiply output without forcing a single lane into an unstable speed push, but the success condition is uniformity—each lane must dose consistently, seal consistently, and stay aligned.

At Rich Packing, the stick pack projects that run most smoothly are the ones where pack dimensions, target output (servings/min), product behavior (flow, dust, viscosity), and film structure are defined early, then sealing and dosing stability are proven at production-like speed before tooling and lane count are locked. That approach keeps the upside of stick packs—speed and user experience—without inheriting avoidable defect rates.

|

Dimension |

Sachet (flat single-serve) |

Stick pack (narrow sachet packaging) |

Pouch (broader formats) |

|

Best for |

Single-serve powders, samples, condiments |

Single-serve powders; controlled pour; on-the-go dosing |

Multi-serve; shelf presence; reclose/spout needs |

|

Typical use moment |

Tear and pour |

Tear and pour with precision |

Pour/scoop/dispense; reclose |

|

Seal options |

3-side, 4-side, back-seal |

Often back-seal or narrow flat styles |

Flat, stand-up, zipper, spout, gusseted |

|

Speed potential |

High (depends on design) |

Very high with multi-lane, but demanding |

Varies widely by pouch type |

|

Common defects |

Seal leaks, wrinkles, fill drift |

Wrinkles, registration drift, lane-to-lane variance |

Handling/fitment leaks, opening defects |

|

Selection “watch-outs” |

Keep seal zone clean; choose film wisely |

Web handling + uniform sealing across lanes |

Filling/holding/opening method dominates |

If you want a familiar, widely compatible single-serve solution, sachet packaging is usually the starting point—then you refine seal style and film to match shelf-life needs and defect risks. If your product is a powder where controlled pouring and portability matter, stick packs are often the better user experience, and multi-lane production is the cleanest path to high output when lane-to-lane stability is engineered in. If the product is multi-serve, needs reclose, or benefits from shelf presence and easier dispensing, pouch packaging typically wins even if the per-unit material is higher.

Choose the format that reduces your most likely failure mode: powders demand stable dosing and clean seals, liquids demand contamination control, and granules demand gentle, consistent filling. When those fundamentals are right, the “format choice” becomes straightforward instead of expensive.

In most industry usage, yes—stick packs are a narrow, long single-serve sachet shape. The key differences are geometry and the tighter demands it places on web handling and lane-to-lane uniformity at speed.

Not exactly. Sachets usually imply small, single-serve flat packs. Pouches are broader and include flat and stand-up styles, zippers, spouts, and many multi-serve formats.

Often sachets or stick packs work well, but film structure is decisive. If oxygen barrier layers like EVOH are used, they’re typically protected in multilayer structures because moisture exposure can reduce barrier performance.

Common causes include product contamination in the seal area (dusty powders, sticky liquids), a too-narrow seal window for the chosen film, or unstable pressure/temperature/dwell time at running speed.

Wrinkles usually come from unstable tension, mis-tracking, inconsistent friction, or film structures that are too soft for the target speed—effects that show up faster in narrow stick packs.

When volume is high enough that you need higher servings-per-minute without pushing a single lane into instability, and your product/film are consistent enough to run multiple lanes with uniform dosing and sealing. A multi-lane stick packing machine is the ideal choice.

https://www.flexpack.org/industry-overview

2. PMMI ProSource: overview of vertical form/fill/seal process (forming collar → tube → fill → seal → cut; top seal becomes bottom of next).

3. Makwell: comparison of 3-side seal, 4-side seal, and back-seal pouch structures.

https://makwell.com/comparing-3-side-4-side-and-back-seal-pouch/